Photovoltaic Module Traceability Barcode Reading Solution

2023-05-31 13:53

Photovoltaic module traceability barcode reading solution

-----Author/Richard Zhang (Bilin Intelligence Technical Support Manager)

Industry and project background

The photovoltaic manufacturing industry is currently in a state of vigorous development. In 2022, the production of polycrystalline silicon, silicon wafers, batteries, and modules in the photovoltaic manufacturing sector had increased by 45% year-on-year; On the application side, the installed capacity of photovoltaic power generation increased by 137.5% year-on-year; In 2022, the export of photovoltaic related products had increased by 113% year-on-year. The rapid development of the photovoltaic industry is partly due to the fact that solar energy, as one of the cleanest energy sources, has always been a long-term development energy route in China and the world today; On the other hand, influenced by the international situation, regions such as Europe have a stronger demand for photovoltaic power generation. As the global leader of the photovoltaic industry chain, China has also faced higher requirements and challenges in terms of production capacity and output.

(Click on to check infoscan recommanded model FV104 / FV105 / FV6X)

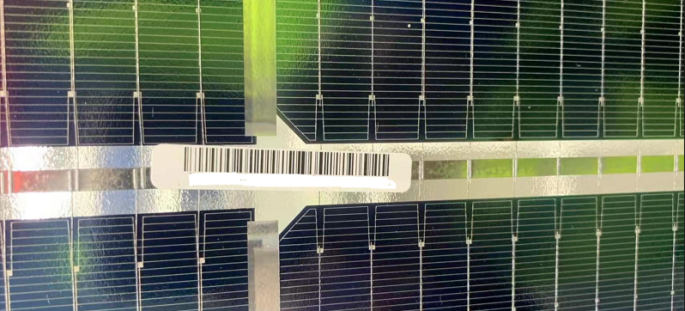

Photovoltaic cell modules are solar power generation devices that directly convert solar energy into direct current. In the production of photovoltaic modules, in order to carry out production control and testing traceability, it is necessary to identify data for each battery module and conduct full process data collection and traceability. Currently, the most suitable data carrier is barcode (including 1D and 2D barcodes). Currently, there are several major issues and difficulties in barcode recognition in the photovoltaic industry, which affect the production efficiency and capacity upgrade of photovoltaic production lines:

➤ Barcode reflective/ frosted film coverage: The barcodes on photovoltaic modules are mostly labeled with high reflective materials such as PET/silver, and are also affixed to the glass surface of the reflective module; Some barcodes may also be directly laser engraved on the glass surface, resulting in stronger reflection; To protect photovoltaic modules, the surface of modules in some workstations will be covered with frosted film, which will cause atomization of barcodes; All of the above have increased the difficulty of barcode imaging and reading;

➤ The range of barcode pasting positions is wide: The size of photovoltaic modules is relatively large, and the current range of barcode pasting is relatively wide. This also requires the industrial barcode reader system to have a broader reading range, while ensuring imaging accuracy and avoiding missing readings;

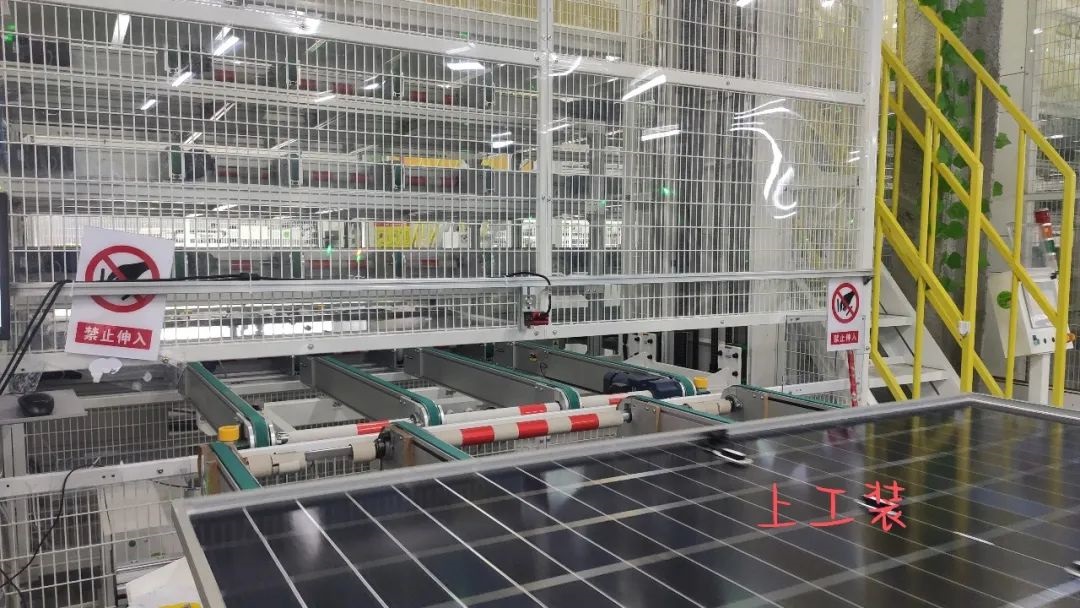

➤ Continuously increasing requirements of production capacity: With the rapid increase in demand in the photovoltaic market and the improvement of quality and efficiency by photovoltaic enterprises, the production line gradually changes from static to dynamic, gradually entering high-speed assembly line production instead of low-speed, with a speed of 1-2m/s; Under the reflective and high-speed applications environment, the success rate of barcode reading will significantly decrease;

➤ Multiple processes and complex application scenarios: The production of photovoltaic modules requires at least 18 processes, of which about 16 require the use of barcode scanners. Different processes involve different reading ranges, object distances, reading speed, and the use of single/multiple barcode readers, therefore, we need solutions with excellent compatibility and adaptability;

➤ Simple and fast installation/cutting: Industrial manufacturing production lines currently expect fast and convenient operation and configuring during equipment installation and cutting. The pace of photovoltaic production is fast, with high requirements for production time and pace. Workers of the production line have higher requirements for configuring experience.

(Click to check infoscan recommanded model FV104 / FV105 / FV6X)

The purpose and significance of project implementation

Bilin Intelligence is a subsidiary of Nanjing Golden Dongkang Information System Co., Ltd., committed to creating world-class intelligent terminal products in the fields of IoT data collection and application such as automatic recognition, machine vision, intelligent sensors, etc. For many years, Bilin Intelligence has assisted many leading customers in the photovoltaic industry in introducing and using industrial fixed barcode readers for production processes and testing traceability, helping to address major concerns of photovoltaic manufacturers.

➤ Promote the digitization and full process traceability of the photovoltaic industry: The adoption of barcodes endows each component with its own "ID card". During the manufacturing process, by reading this "ID card", manufacturers can use MES or related software to monitor the status of components in the entire process in real-time, and also obtain relevant status of the production line, providing data support for quality control, order tracking, and handling capacity bottlenecks. In the circulation and use process of the component after it is offline, by reading this "ID card", the end customer can also obtain important information about the component, thus achieving a closed-loop of the whole process and truly completing the traceability of the entire process.

➤ Improving product quality: The production process of photovoltaic modules is complex and involves a large number of testing steps (such as appearance testing, power testing, safety testing, etc.). By collecting data on the barcodes on the components in each process, manufacturers can know whether the components have been completed with all manufacturing processes and passed various testing and inspection items, thereby ensuring that this component is a qualified product. At the same time, it can also track and handle various quality and process issues in a timely manner through problem feedback in the testing process.

➤ Explore and improving production capacity: The production capacity improvement of photovoltaic module production lines is also a key focus of manufacturers. Through the collection of component barcodes in the manufacturing and testing processes and the real-time processing and summary of data by the MES system, manufacturers can clearly understand the manufacturing cycle of components, identify production capacity bottlenecks in product manufacturing, and optimize the process. At the same time, it is also possible to optimize and upgrade the production line in a reasonable manner, such as increasing the number of time-consuming process equipment and removing redundant waiting times, etc.

In this process, Bilin Intelligence has carried out a series of specialized designs and considerations in its products and solutions based on the characteristics and application requirements of photovoltaic barcode reading - from algorithm design, software and hardware, on-site system construction, and other aspects to improve the reading rate, while meeting the reading requirements of high-speed/accelerated production of photovoltaic module. (Click to check infoscan recommanded model FV104 / FV105 / FV6X)

Overall plan design and implementation of the project

➤ Design and breakthrough of core technologies

In order to implement the photovoltaic barcode reading and tracing project, it is necessary to first focus on the core issues of photovoltaic module manufacturing, specifically design and break through the core technology, in order to lay the foundation for system construction. To this end, we have designed in several aspects, and the achievements or results are described as follows:

· In terms of light source design: Introducing a high reflectivity reflective cup light source design and a high reflective coating, the lighting intensity can be increased by more than 50% under the same lighting power, significantly improving the dynamic code reading speed by more than 30%; Meanwhile, equipped with a rich design of light source components, using polarization and atomization design, for photovoltaic barcode and glass reflection, there will be significant image improvement; By increasing lighting intensity and combining polarization atomization design, the joint improvement of high-speed and anti-reflective imaging is ultimately achieved;

· In terms of decoding algorithm: The decoding algorithm is the core of barcode reading. In terms of decoding methods, several improvements have been made to focus on the application of photovoltaic technology. On the one hand, in terms of barcode finding and positioning, the introduction of multi-core processing and intelligent search algorithms greatly reduces the code finding time; At the same time, for barcodes that are difficult to decode due to frosting, ultra-high resolution imaging restoration algorithm technology is introduced to greatly restore barcodes and ensure reading;

· On autofocus: Introducing TOF fast zoom technology to achieve faster and more dynamic focusing on the basis of the original image focusing, in order to meet the distance requirements of different workstations;

· On rapid device configuring: In terms of automatic parameter configuration, in order to facilitate and ensure the fast and barrier-free configuration of the barcode reader system for the production line workers at each station, Bilin Intelligence has made great investment in the design and optimization of the automatic parameter adjustment algorithm. The parameter adjustment time is within 30 seconds, and the obtained parameters have strong matching and fitness, which has played a fast and convenient role in the operation of production line.

(Click to check infoscan recommanded model FV104 / FV105 / FV6X)

➤ Design and implementation of typical photovoltaic workstations

Barcode reading and tracing of the laminator workstation (Click to check infoscan recommanded model FV104 / FV105)

Barcode reading and tracing of pressure testing machines (Click to check infoscan recommanded model FV104 / FV105)

Barcode reading and tracing of upper/lower installation testing stations (Click on infoscan recommanded model FV104 / FV105)

Implementation effect and achievements

By designing a system for reading and tracing nearly 20 processes in the production process of photovoltaic modules, the barcode reader and system designed by Bilin Intelligence can meet all requirements optimally. We have solved problems such as reflection, frosting and atomization, wide angle and high-speed.

Today, various industries are in the stage of industrial upgrading and rapid rise, and industrial automation is rapidly covering. Bilin Intelligence will also make innovative breakthroughs in product, technology, and industry applications in terms of barcode reading, OCR and RFID recognition, 2D and 3D visual inspection, etc., to assist industrial intelligent manufacturing, create value for customers, and achieve win-win results!

Get the latest price? We'll respond as soon as possible(within 12 hours)