How To Read DPM Code With Reflection

2022-11-22 13:51

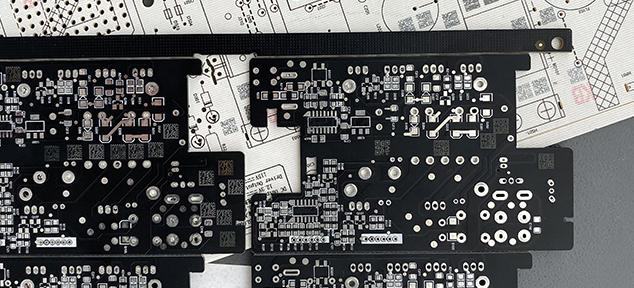

The full name of DPM is Direct Part Mark (direct parts mark).

It is a special logo marking technology.

This technology can realize marking directly on the surface of parts without the need of marking carriers such as paper and labels and can directly form graphics and texts on the surface of parts that are firm and even have the same lifespan as the parts.

Compared with traditional barcodes or labels For example, the DPM code can become a fixed part of the product itself, which will not be lost and cannot be altered for life time. There will be no interference when the product continues to be processed.

Along with the entire life cycle of the product, the traceability of the product is realized. Therefore, the DPM code has been widely used in product quality traceability and tracking management in many industries.

(Click on to check infoscan recommanded model FV2X0 / FV105 / FV104 / FV6X / FV3X / HS3050 / HS3260 / HS3155)

When reading a DPM code attached to a metal part, the clarity will be affected by the reflective properties of the metal, which increases the difficulty of reading the code. Among the infoscan series products, the infoscan FV100 series readers are equipped with a polarizing filter which can be used on a highly reflective surface so as to realize much ideal lighting, easy to obtain barcode information.

Barcodes under conditions like below can be identified and read by infoscan readers:

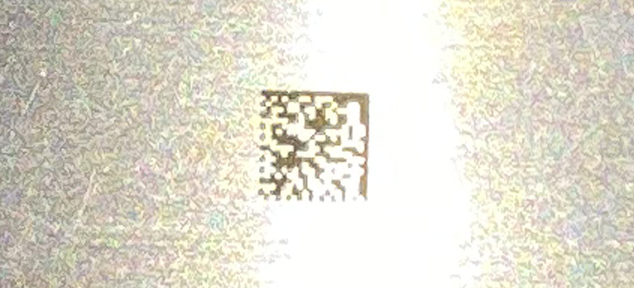

Highly reflective scene

(Click on to check infoscan recommanded model FV2X0 / FV105 / FV104 / FV6X / FV3X / HS3050 / HS3260 / HS3155)

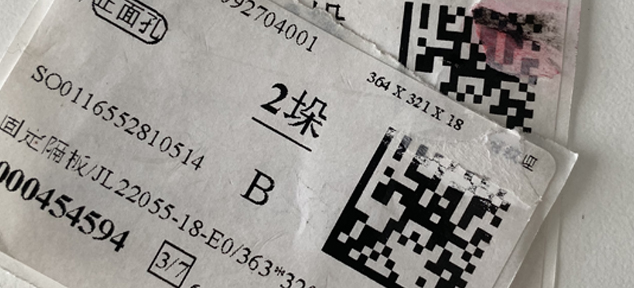

Scenes with poor defacement quality

low-contrast scene

infoscan FV series products' powerful image processing and decoding algorithm with rich lighting units satisfy most industrial applications with excellent performance. (Click on to check infoscan recommanded model FV2X0 / FV105 / FV104 / FV6X / FV3X / HS3050 / HS3260 / HS3155)

Get the latest price? We'll respond as soon as possible(within 12 hours)